Applications

Robots have historically been taught manually, i.e. using the robot's 'teach pendant' to manually drive the robot's TCP to the desired

point along the part to be operated on, while visually verifying – as much as feasible – the achieved accuracy. This is obviously

a time-consuming process, to be painstakingly repeated for each (relevant) point along the robot's path in space; furthermore, this

process clearly doesn't...[more...]

Whether a particular robot-cell has been initially put in service using traditional manual robot programming methods (with the teach

pendant), or through Off-Line Programming Simulation-based techniques, that robot-cell might need to be duplicated. This is often

the case when the level of production output requires multiple 'identical' robot-cells to perform the same task. Instead of painstakingly

reprogramming...[more...]

Whether a particular robot-cell was originally programmed manually, or through Off-Line Programming (see "Off-Line Programming with

No Touchup"), it is imperative to maintain the positional accuracy of these original robot programs throughout production – despite

the many hazards encountered on any plant floor: for example...[more...]

Those same 'Recovery' calibration tools allowing one to maintain a robot-cell's initial Absolute Accuracy (see "Maintain your Robot's

Accuracy throughout Production") offer an additional critical benefit: reduce robot downtime – following a sudden tool crash, replacement

of a worn out transmission mechanism, replacement of a robot motor, etc. – to a minimum!

The roPOD™ and the AccuBeam™ systems are In-Line Recovery Calibration...[more...]

The roPOD™ and the AccuBeam™ systems are In-Line Recovery Calibration...[more...]

A robot is generally capable of repeating the same move towards a specific point in space, over and over, within a high level of tolerance

(referred to as 'unidirectional Repeatability'), generally well below 0.1mm. But this does not mean that that particular point in

space is well known relative some global coordinate frame (such as the robot base frame): the level of 'Absolute Accuracy' achieved

by an 'off-the-shelf'...[more...]

Robotic applications such waterjet cutting, laser cutting, applying a bead of sealant, arc-welding, etc. are generally 'path-intensive',

in that such applications require the Robot's TCP to accurately follow a specific path along a part (located on a fixture), and that

such path is often formed by a series of points at a rather close distance from one another (depending on the path's shape). Such

paths are typically good candidates for Off-Line Programming: the part, and the desired...[more...]

Manufacturing plants in all industries require ongoing inspection of their production parts, to monitor consistency and quality of

the production process. Typical part features to measure are the diameter and the location of a hole (circle, slot, etc.), the location

of an edge, the distance to a surface, the location and length of studs, etc. Historically, off-line measuring systems, such as CMM's,

have been used to measure random part samples removed from the production...[more...]

One typical issue to deal with in various robotic applications is the variation from part to part of the location of the fixture holding

the part the robot is operating on; another typical case is simply the variation of (the location of) the part itself within the fixture.

So, while robot calibration can accurately compensate, at the launch of the production line, for errors in the 'metrological chain'

formed by the robot, the end-effector, the fixture, and optionally external axes and/or a positioner...[more...]

Some robot applications require the highest possible accuracy – close to the robot's repeatability, i.e. typically < 0.1mm – which

robot-cell calibration alone cannot achieve, especially in the case of external dynamic forces (e.g. the pressure exercised by drilling).

The required accuracy should be achieved not just at the robot's final resting position (as is the case in Robot Guidance – see "Robot

Guidance for Part-to-Part Variation") but along the entire path followed by the robot's...[more...]

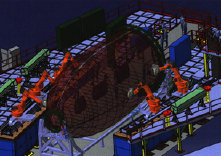

Drilling, Routing, Trimming and other machining operations are high-force applications historically handled by dedicated equipment,

such as CNC's. To increase flexible manufacturing and to reduce cost, robots are more and more used in such applications, with heavy

sophisticated end-effectors mounted at their ends. Aerospace is one industry in particular where such installations are becoming prevalent...[more...]

In today's world of flexible automation, end-users must be able to rely on the performance of their robot when executing various programs

and applications. The ISO 9283 International Standard and the RIA 15.05 Standard define the performance criteria and related testing

methods to quantify performance characteristics of manipulating industrial robots. These criteria and tests assess the static and

dynamic performance of a robot...[more...]

Most of Dynalog's products require a solid communication line and reliable integration not only with the robot controller, but with

other equipment as well, such as with numerous measurement devices, with different PLC's, and with customers' data servers. The need

to 'Filter' robot programs with the...[more...]

Automated In-Line Gauging

About Us

Applications

Products

About

DynaCal

DynaFlex

CompuGauge

roPOD

AccuBeam

DynaGuide

Robot Guidance for Part-to-Part Variation

Absolute Accuracy Robot Calibration

Off-line Programming with No Touchup

Robot Performance Analysis

Contact Us

{Copyright (C) 2023 Dynalog, Inc. All Rights Reserved}

Duplicate Robot Programs with No Touchup

Maintain your Robot's Accuracy throughout Production

Minimize Robot Downtime

Accurate Cutting, Sealing, Welding with your Robot

Adaptive Robot Control for Ultimate Accuracy

Targeted Robot Communication Solutions

Turn your Robot into Precision Machining Equipment

Automated In-Line Gauging

About Us

Applications

Products

About

DynaCal

DynaFlex

CompuGauge

roPOD

AccuBeam

DynaGuide

Robot Guidance for Part-to-Part Variation

Absolute Accuracy Robot Calibration

Off-line Programming with No Touchup

Robot Performance Analysis

Contact Us

{Copyright (C) 2023 Dynalog, Inc. All Rights Reserved}

Duplicate Robot Programs with No Touchup

Maintain your Robot's Accuracy throughout Production

Minimize Robot Downtime

Accurate Cutting, Sealing, Welding with your Robot

Adaptive Robot Control for Ultimate Accuracy

Targeted Robot Communication Solutions

Turn your Robot into Precision Machining Equipment